Dear customers and friends:

Fastenboen's Chrome Button Head Screws represent a significant advancement in fastener technology, combining precision engineering with superior material science. These screws are designed to meet the rigorous demands of industries such as aerospace, automotive, and medical equipment, where reliability and performance are non-negotiable. This article delves into the product's core features, technical specifications, and real-world applications, supported by authoritative references from the National Institute of Standards and Technology (NIST).

Core Features and Technical Innovations

Optimized Load Distribution

The Chrome Button Head Screws feature a radially curved bearing surface that minimizes point loading on soft substrates like composites and cast alloys. This design reduces the risk of material deformation, ensuring even stress distribution across the contact area. According to NIST's research on material testing standards, such innovations are critical for applications requiring high load-bearing capacity without compromising structural integrity.

Head height tolerance is tightly controlled at ±0.20mm, significantly tighter than the DIN 912 standard (6.0mm for M6 screws). This precision ensures consistent performance in critical assemblies, as highlighted in NIST's metrology guidelines.

High-Torque Drive System

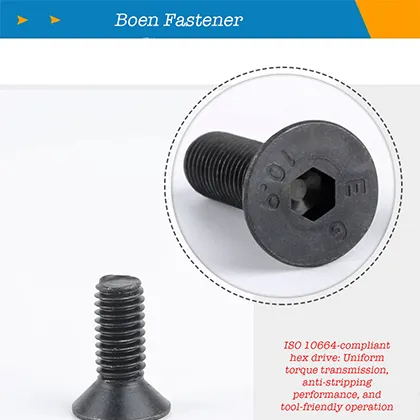

The extended socket depth (≥1.5× nominal diameter per DIN 7991:2014) allows for enhanced torque transmission, reducing the risk of stripping during installation. The drive conformity meets ISO 10664 Class C standards with a tolerance of ±0.028mm, ensuring compatibility with modern power tools. NIST's precision engineering research underscores the importance of such tolerances in industrial applications.

Performance-Graded Materials

Available in 12.9/10.9/8.8 strength classes, these screws are manufactured from SCM435 alloy steel, providing exceptional tensile strength and durability. Corrosion resistance is further enhanced through black oxide coating (≥96h salt spray) and Geomet® coating (≥720h). NIST's materials testing protocols validate the effectiveness of such protective coatings in harsh environments.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Head Height Tolerance | ±0.20mm (e.g., M6: 4.0mm) |

| Socket Depth | ≥1.5× Nominal Diameter |

| Drive Conformity | ISO 10664 Class C (±0.028mm) |

| Material Strength Classes | 12.9/10.9/8.8 (SCM435 Alloy Steel) |

| Corrosion Protection | Black Oxide (≥96h Salt Spray), Geomet® (≥720h) |

| Head-to-Shank Transition Radius | ≥0.1d (vs. DIN's ≥0.08d) |

Key Applications

Aerospace

In aerospace engineering, the reduced head height of Chrome Button Head Screws contributes to weight savings in turbine assemblies. NIST's aerospace measurement standards emphasize the importance of lightweight, high-strength components for fuel efficiency and performance.

Automotive

The radially curved head design prevents thread galling in aluminum engine blocks, a common issue in high-torque applications. NIST's automotive materials research highlights the need for such solutions to enhance vehicle reliability.

Medical

Passivated stainless steel variants meet ISO 13485 biocompatibility standards, making these screws ideal for surgical instruments and implantable devices. NIST's medical device testing protocols underscore the critical role of material purity in healthcare applications.

Precision Engineering

The enhanced stress concentration reduction (≥0.1d transition radius) ensures longevity in precision machinery. NIST's metrology research supports the use of such designs in high-precision manufacturing environments.

Company Background and Expertise

Shijiazhuang Dellee Ming Garments Co., Ltd., the manufacturer of these screws, has over 20 years of experience in global exports. Their expertise in international logistics and compliance ensures seamless delivery to clients worldwide. The company's commitment to quality is reflected in their detailed product specifications and instant quote responses, as noted in their product documentation.

Comprehensive Service Offerings

- Reliable After-Sales Support: Swift resolution for technical issues and product inquiries.

- Global Export Expertise: Proven experience in international logistics and compliance.

- Customizable Specifications: Detailed spec sheets for informed purchasing decisions.

- Timely Shipment: Certified export documentation and pre-shipment visual verification.

- Competitive Pricing: Premium quality optimized for value and performance.

Conclusion

Fastenboen's Chrome Button Head Screws exemplify the intersection of advanced engineering and material science. By adhering to stringent standards and leveraging NIST's metrology and materials research, these screws set a new benchmark for reliability in critical applications. Whether in aerospace, automotive, or medical industries, their innovative design ensures optimal performance and durability.

References

National Institute of Standards and Technology (NIST) - Authority in metrology and materials research. https://www.nist.gov/

Fastenboen Product Page - Detailed specifications and technical data.

Post time: Aug . 14, 2025 02:10